Muhlen Sohn

Corrugator Belts

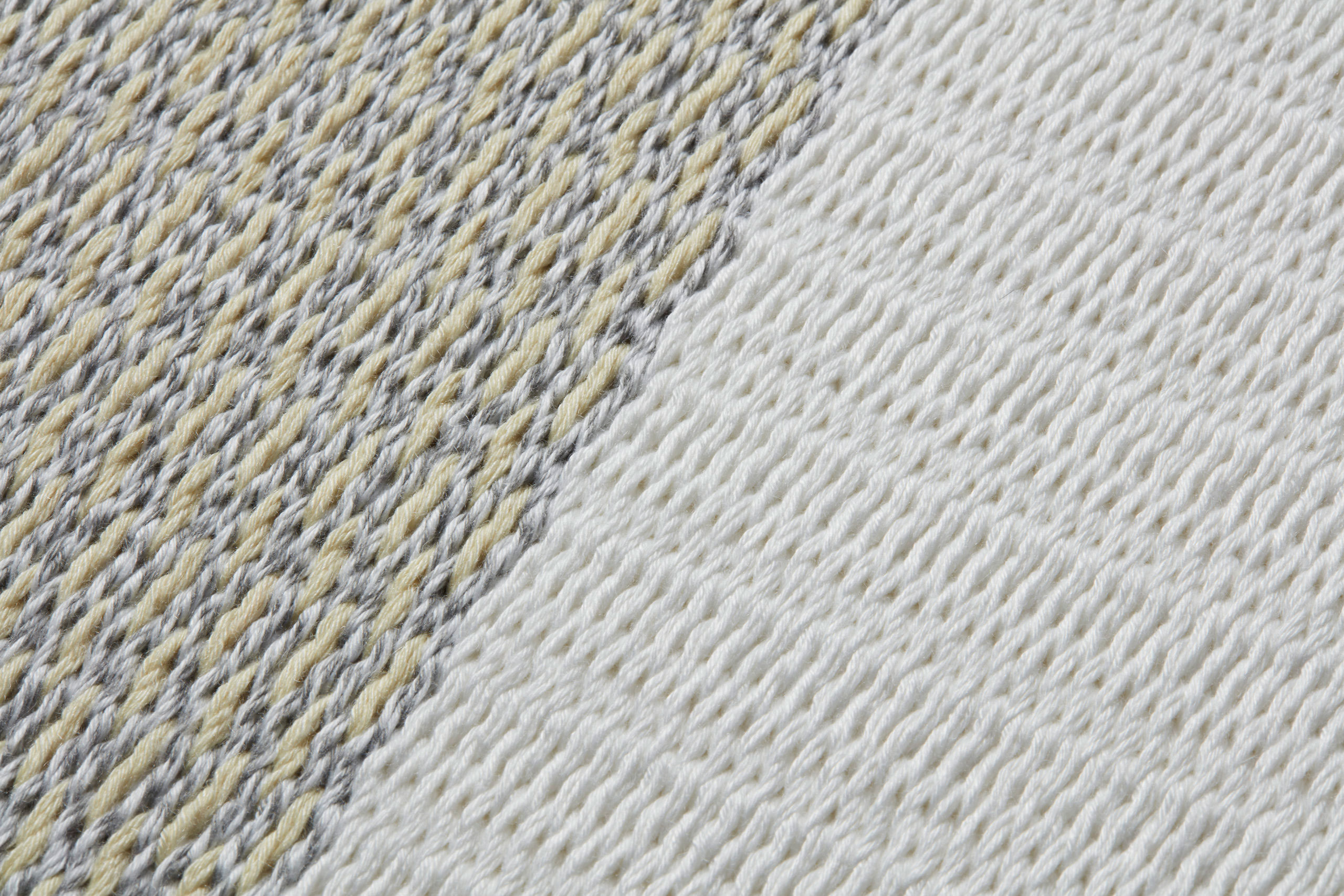

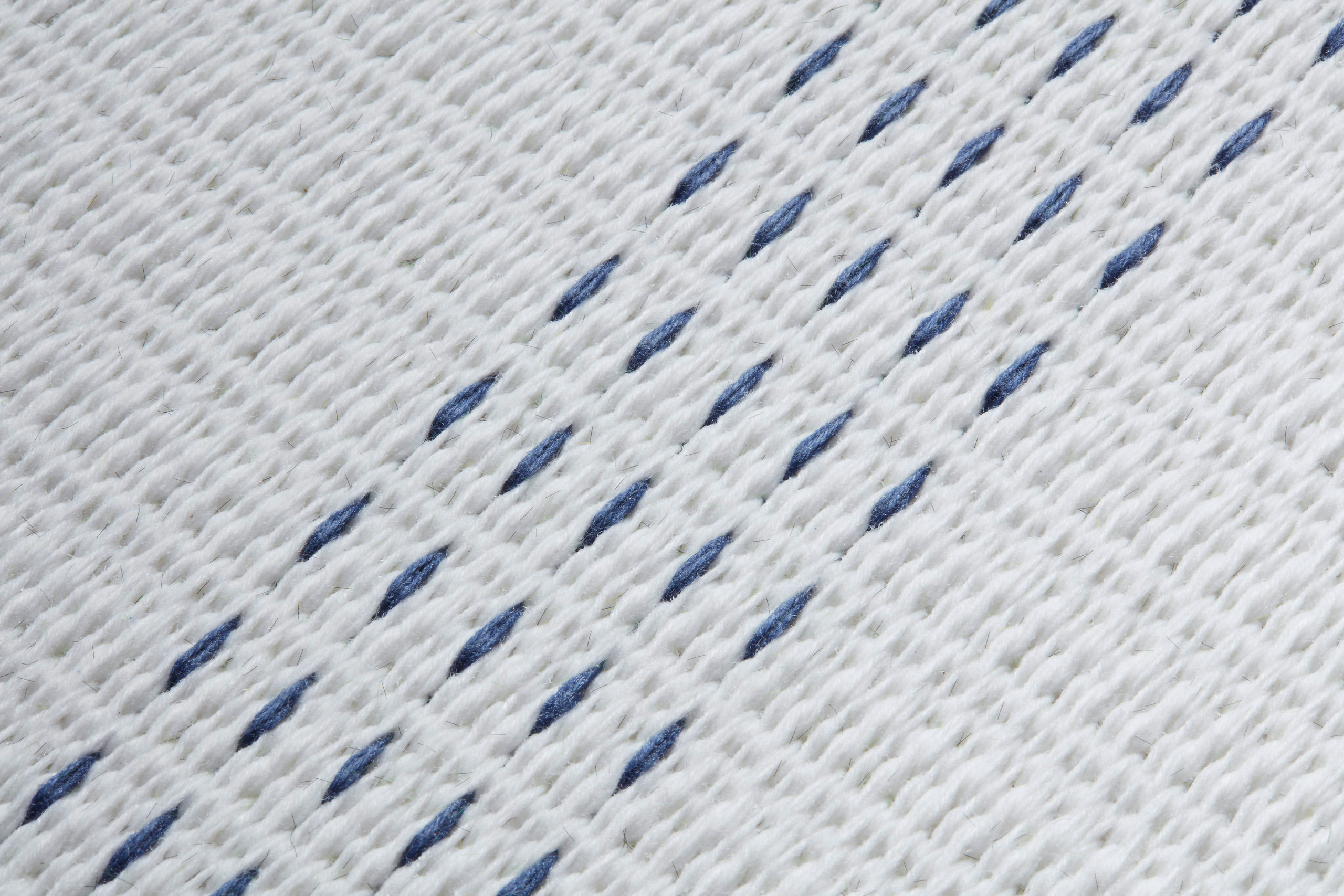

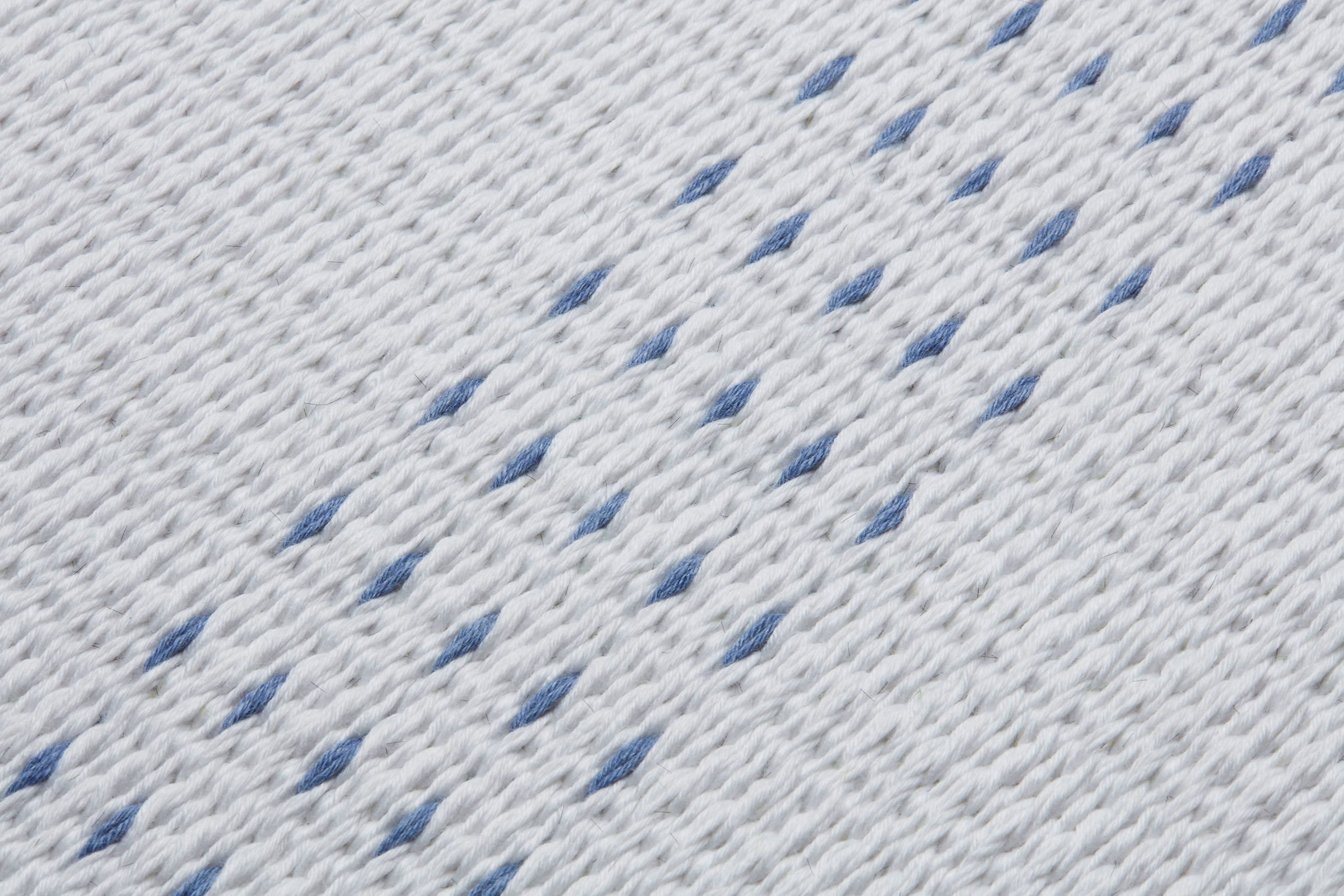

Our Muhlen Sohn corrugator belts are of the highest quality. The basis for this is above all permanent innovations and developments – protected by patents.

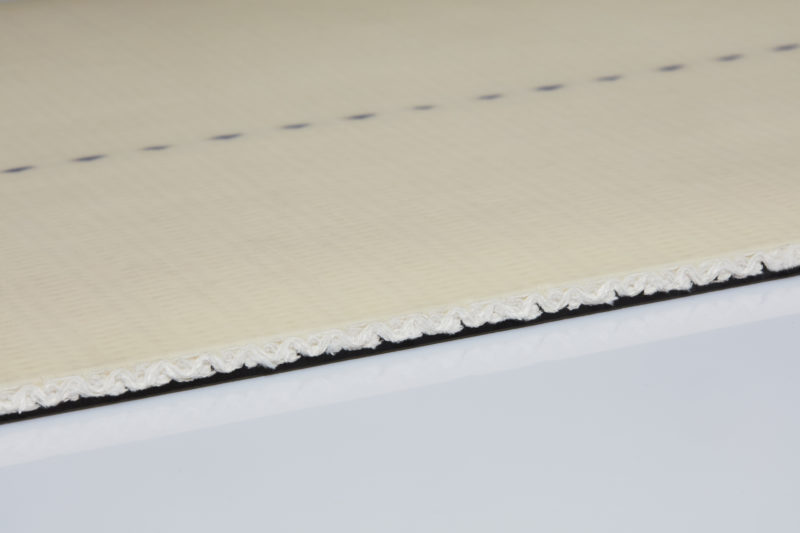

The multi-layer weaving with highly hygroscopic yarns guarantee optimal moisture management and even bonding, even at high production speeds.

Thanks to the dense, patented weaving structure, the roller pressure is distributed over the entire area.

Application within a corrugating machine

- Top Belts

- Bottom Belts

- Drum Laggings

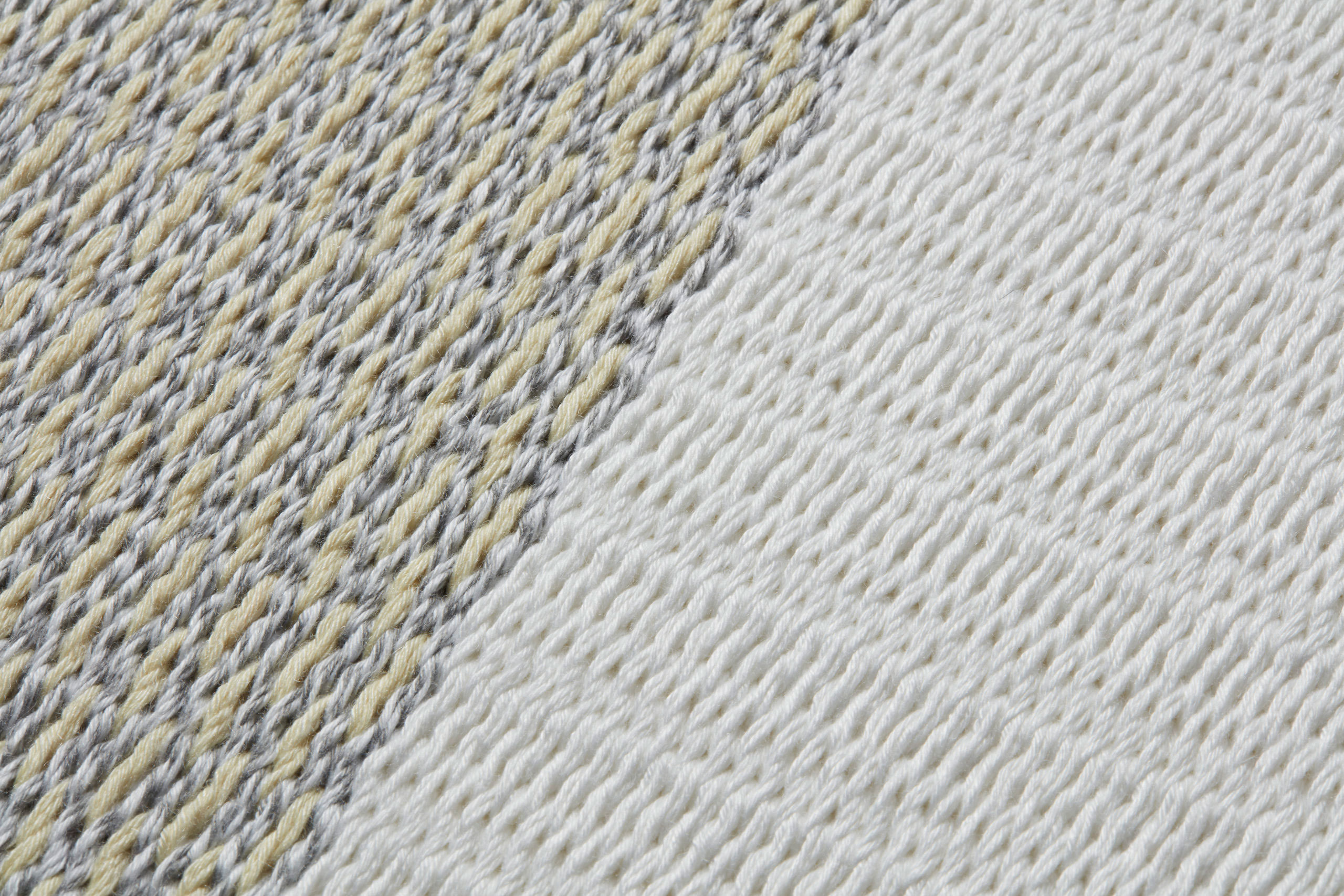

AQUA PULL S

- Universal bottom belt

- Basic bottom belt for the universal usage in double backers

AQUA PULL AE

- Top belt suitable for all corrugators

- Special hybrid aramid edges offers a unique feature combination of moisture management and higher abrasion and temperature resistance at the edges of the belt

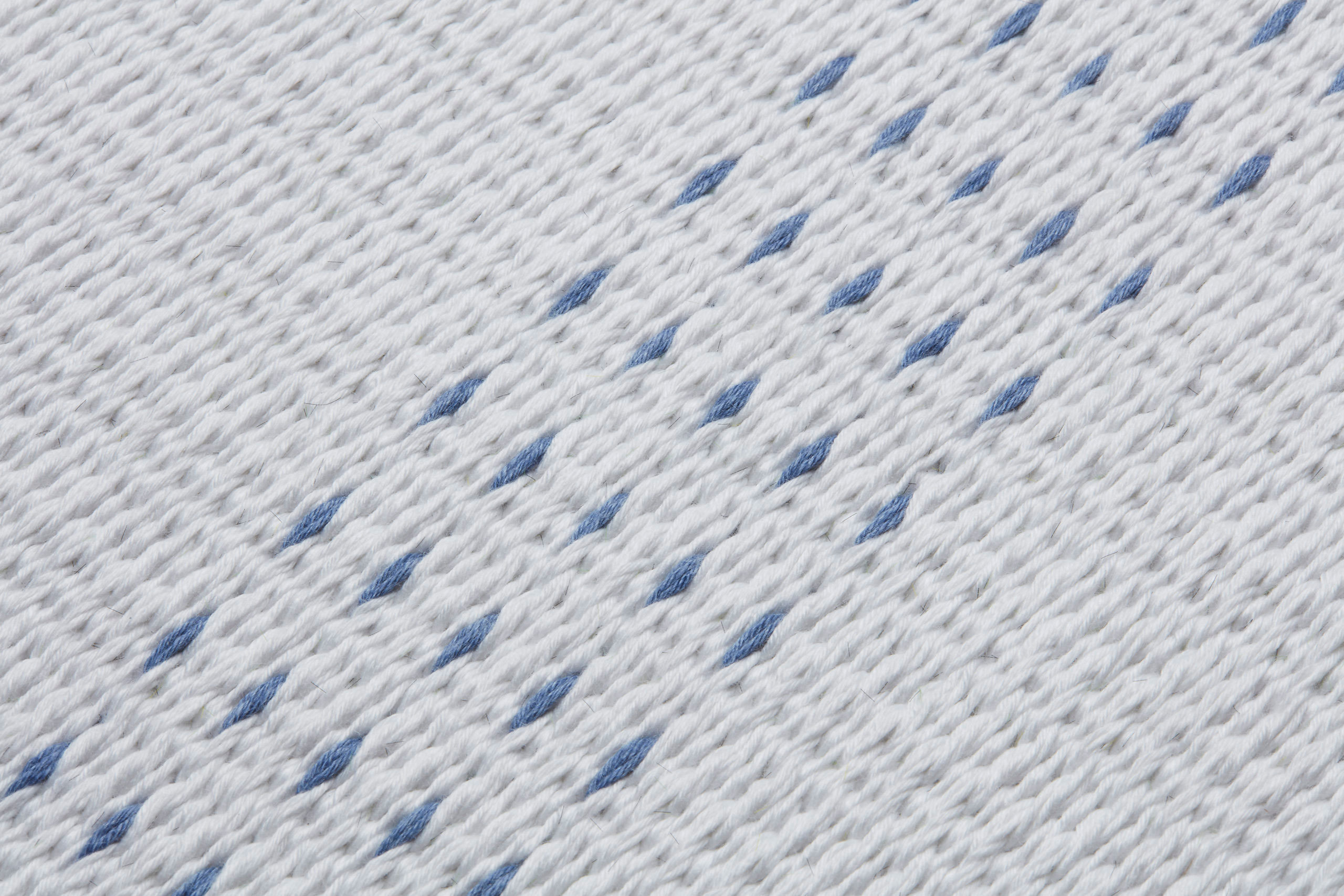

AQUA ULTRA AE

producing a lot of micro flutes

- Particularly suitable as a top belt for high-speed corrugators (maximum speed possible)

- Particularly for micro flutes (fine and extra thin flutes)

- Open weaving structure for steam evaporation, also at higher speeds

- In-woven aramid reinforcement for higher temperature and abrasion resistance at the edges

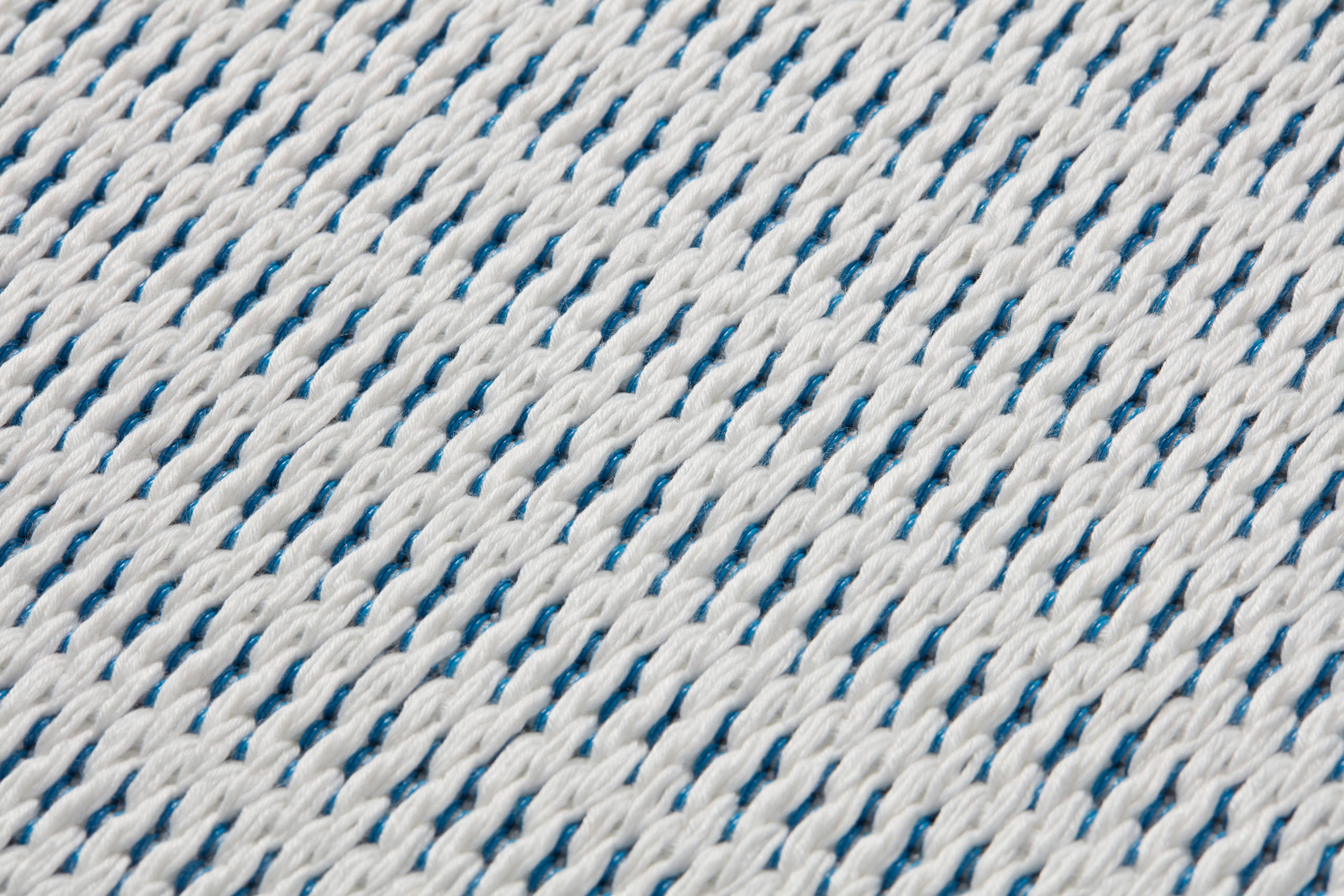

AQUA RUN AE

producing a lot of heavy boards

- Particularly suitable as a top belt for high-speed corrugators (maximum speed possible)

- Particularly for heavy boards (>25 %), double and triple wall, but also suitable for fine and micro flutes

- Open weaving structure for steam evaporation, also at higher speeds

- In-woven aramid reinforcement for higher temperature and abrasion resistance at the edges

MAX PULL S

- Bottom belt for increased demands concerning the paper transport

- Special silicone coating

- Especially for heavy or smooth boards and rough paper surfaces

- Also for the use in semibeltless systems as bottom and top belt

MAX PULL ANTISTATIC

- Bottom belt with a high-grip traction layer of silicone

- Additionally, with a special combination of antistatic yarns for the safe discharge of electrostatic charges

- Especially for heavy or smooth boards and rough paper surfaces

- Useful for the safe discharge of electrostatic charges

AQUA PULL ANTISTATIC

- Bottom belt with especially developed yarn combination (antistatic yarns)

- Useful for the safe discharge of electrostatic charges

Muhlen Sohn Corrugator Belts

Characteristics

- Unique, patented weaving structure

- High density multiple layer fabrics

- 100 % synthetic and highly hygroscopic fibers

- Optimal moisture absorption and release

- Excellent cross stability and stiffness of the belt

Advantages

- High quality for a long lifetime (less belt exchange costs)

- High moisture absorption and release

- Maximum production speed possible (more output)

- Optimal paper pull

- Excellent straight running characteristics and smooth transport

- Fast drying and uniform bonding of the board (less waste)

Drum Laggings

In order to optimize your production processes, Muhlen Sohn offers you corrugator belts as well as the right accessories to support your work.

Worldwide customer service

Whether in America, Europe or Asia, your contacts are nearby. Our sales partners provide excellent customer service.

24 hours a day, 365 days a year – you can always reach us, and a fast reaction time is guaranteed.

For urgent cases outside business hours, our emergency number is available.

Service Emergency Number for corrugator belts:

+49 7304-801333

Media &

Downloads

Do you need more detailed information about our corrugator belts? Then take a look at our brochure.

Or contact us directly. We are happy to help you with your request and answer your questions!